Aluminum Composite Navard Aluminum MFG.

Sandwich panel is a structure made of Many layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

What is Aluconam:

It is a sort of aluminum compounded panel compassed of two layers of aluminum and a polyethylene core pressed at its center.

Aluconam application:

Building facades, gas stations, bridges, special buildings (airports, subway stations,… ), internal cover of tunnels, corridors and interior decoration of offices and public buildings.

Color Chart

Advantages of Aluconam products compared to similar products in construction industry:

Aluconam products have wide application in construction industry.

The initial objective of composite panels was production of a material that would serve in lightening of building weights and offer a complete freedom in its architectural design. It was subsequently diverted to other industries as well. It is noteworthy that the advantages of Aluconam are by no means restricted in lightening building weights but it has many other benefits that are shown below.

1- Reduction of related expenses.

2- Facilitating forming and shaping procedures.

3- Removing restrictions in in utilizing different design ideals.

4- Keeping the paint durable without any change during forming operation.

5- Diversity of color and elimination of sun rays reflection.

6- Resistance against acidic rains and ultra violet rays.

7- Elimination of continuous cleaning.

8- Easy and variant infrastructure.

9-Possibility of replacing panels

10- Easy installation

11- Sound and heat insulation.

Advantages of Aluconam panels compared to other aluminum panels.

Production of aluminum panels at Navard enjoys a number of advantages due to utilization of Nash hot mill technology.

1- Purchase internal made product with high quality at competitive prices.

2- Guarantee for fifteen (15) years

3-Work insurance for ten (10) years

4- Factory standard NO. 39/86/00012 applied for production of Aluminum composite panels.

5- Availability of products any time required.

6- Production of products in a variety of colors as required by the customers.

7- Production in dimensions those are not common

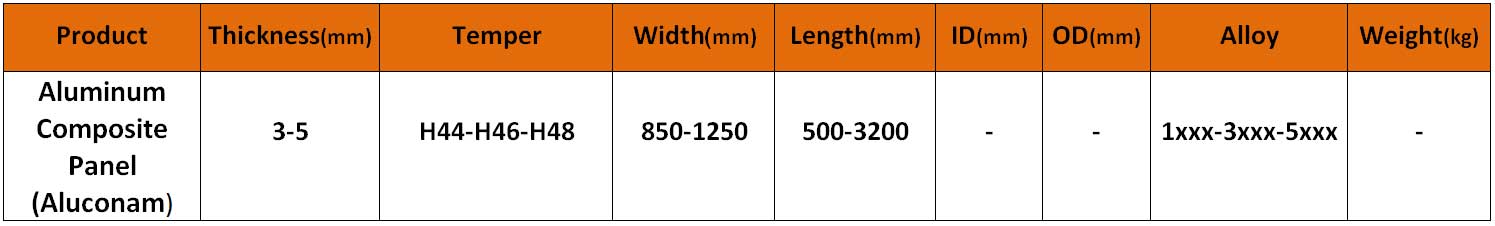

1-Production with length more than 3200 mm is possible under special condition. 2-color of product base on color chart 3- Possibility of production with requested color as required by the customer 4- Production of mirror sheet is possible. 5- Production of designed sheet is possible.